- +687 76.12.16

- monday to friday 7h30 – 12h / 13h – 17h

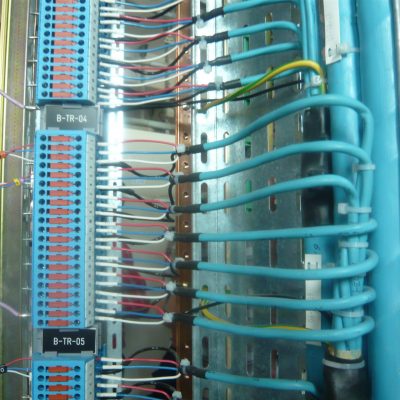

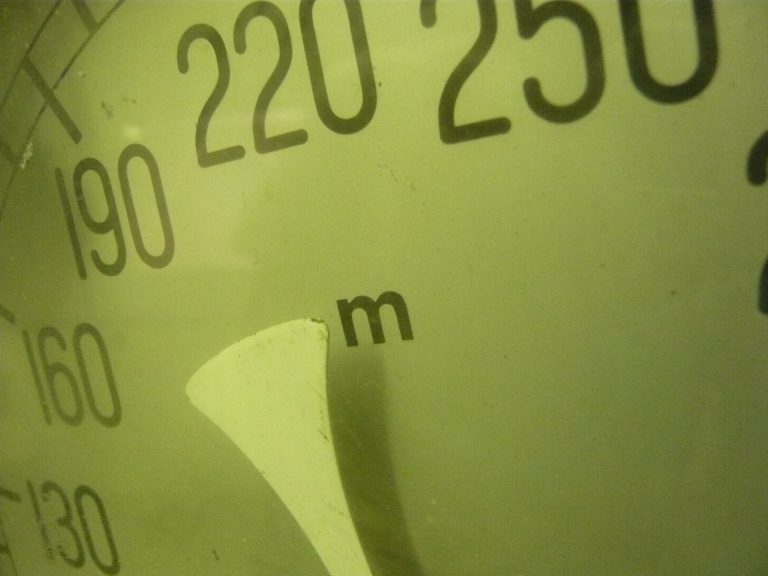

Instrumentation and Metrology

COMEP is your partner in metrology. We can carry out the calibration and verification of your measurement, temperature and pressure equipment on site or in our workshop with our COFRAC calibration certificates.

We support you in the management of your measurement equipment and in the improvement of control loops.

Our services

- Calibration and verification of your temperature and pressure measuring equipment on site or in our workshop with our COFRAC certified calibration certificates.

– Calibrations reveal deviation of an instrument and its evolution over time.

– Verifications guarantee that the indications given by a measuring instrument comply with requirements. - Support in the management of your measuring equipment.

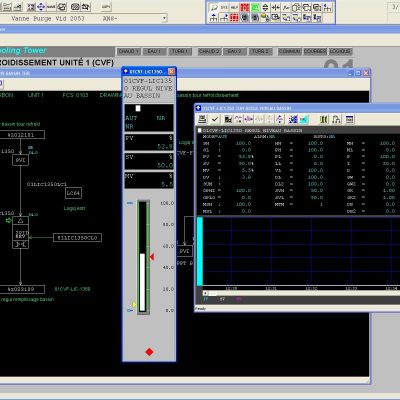

Study of your needs, obligations and structure of the monitoring of your measuring equipment. - Improvement of control loops.

Guarantee the operating points, quality homogeneity of your productions and better energy control of consumption optimisation. - COMEP FORMATION supports you in your search for knowledge with adapted training modules, whilst also validating of your acquired knowledge.

Managment of your measuring equipment

Instrument monitoring structures require organization and questioning of the “real” needs linked to their use.

This process allows the control of the measuring instruments and therefore the quality of measurements carried out.

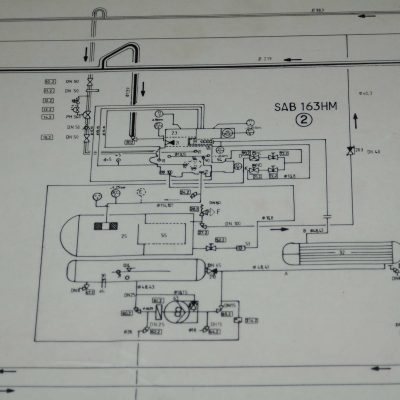

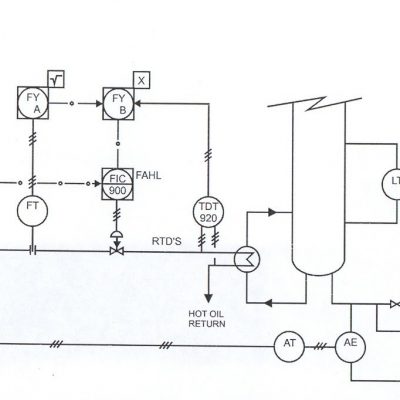

Making your control loops more reliable

The study and improvement of your control loops will guarantee:

- operating points

- the homogeneity of the quality of your production

- better energy control of consumption.

Metrology (in brief)

Metrology: a tool at the service of businesses

A tool of innovation and competitiveness, its challenges are qualitative, economic and lead to greater control of manufacturing processes and reliable product quality. Nowadays, industrial metrology is essential for businesses to comply with quality standards such as ISO 9000, ISO 14001 as well as environmental and transactional regulations.

Deliberation No. 35/CP of New Caledonia (October 6, 2006) relating to the control of measuring instruments specifies:

“Every user has the obligation to ensure the suitability for use, accuracy, good maintenance and operation of the measuring instruments used in the course of their activities.”

Metrology for security

Risk = probability x severity x non-detectability

The majority of security systems relies on measurement information, carrying out validity tests reduces non-detectability and therefore risk.

Our Instrumentation and Metrology engineer: Hervé SCHOLASCH

Graduated from ENSTIMA (Ecole Nationale Supérieure des Techniques Industrielles et des Mines d’Alès). His career has taken him from mining to process control and metrology.